16. November 2022 No Comment

Although now limited in many locations due to its negative environmental impacts, cyaniding still occurs in low tech production settings. It just takes longer for the core of a large part to reach the required temperature.

martensitic formation, allowing it to obtain features and properties that it Hardness obtained is slightly higher than . engineeringenotes.com All rights reserved. We supply global solutions from our headquarters in Greenville, South Carolina. Over the course of this process, the metals properties will change. Through Hardening.

While shopping for fasteners, one major decision that you will have to make will be about which material to get it in. The case depth is rarely more than 2.5 mm. These shops What is Design Review?  Ferrous metal alloys and steel undergo carburizing by remaining for several hours in a carbon-rich environment at high temperatures. For depth of hardening, Steen and Courtneys relationship is: but with a considerable scatter of experimental data.

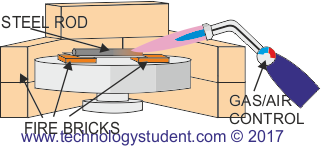

Ferrous metal alloys and steel undergo carburizing by remaining for several hours in a carbon-rich environment at high temperatures. For depth of hardening, Steen and Courtneys relationship is: but with a considerable scatter of experimental data.  The colors are not in the steel, they are nitrides and oxides of manganese, phosporous, and iron on the surface. 7. A design review of an oil and gas project is a comprehensive evaluation of the technical design and engineering of the project, aimed at identifying any potential issues or risks that could impact Hi There! Lets take a closer look at them. can you put foil in a fan oven; walgreens dot physical; lee stryker plane crash; michael j rubin florida What Is Stainless Steel? In one technique, the time above the transformation temperature (A3) can be skillfully increased. The presence of larger amount of retained austenite is not desirable. The significant work hardening behavior of Inconel 718 can improve the service performance of components; nevertheless, it cause extreme difficulty in machining. In mass production work, progressive surface hardening is carried out where it is arranged to have the flame in progress along with quenching. WebThis study aimed at investigating job-related challenges faced by Iranian EFL junior and high school teachers during their professional jobs as English language teachers. After progressive heating, quench jets cool the heated section.

The colors are not in the steel, they are nitrides and oxides of manganese, phosporous, and iron on the surface. 7. A design review of an oil and gas project is a comprehensive evaluation of the technical design and engineering of the project, aimed at identifying any potential issues or risks that could impact Hi There! Lets take a closer look at them. can you put foil in a fan oven; walgreens dot physical; lee stryker plane crash; michael j rubin florida What Is Stainless Steel? In one technique, the time above the transformation temperature (A3) can be skillfully increased. The presence of larger amount of retained austenite is not desirable. The significant work hardening behavior of Inconel 718 can improve the service performance of components; nevertheless, it cause extreme difficulty in machining. In mass production work, progressive surface hardening is carried out where it is arranged to have the flame in progress along with quenching. WebThis study aimed at investigating job-related challenges faced by Iranian EFL junior and high school teachers during their professional jobs as English language teachers. After progressive heating, quench jets cool the heated section.  The main disadvantage of induction hardening is its cost. Metals may undergo a plethora of annealing techniques such as recrystallisation annealing, full annealing, partial annealing and final annealing. The working lifespan of the component also increases. 17. Normalising creates a uniform grain size and composition throughout the part. Ageing, however, only elevates the temperature to medium levels and brings it down quickly again. During the holding or soaking stage, the metal is kept at the achieved temperature. The higher the temperature used, the softer the final workpiece becomes. Currently, I work in a reputed MNC as a Senior Piping Stress Engineer. The other main operating variables to be skillfully controlled are: (i) The distance between the inner cone of the flame and the surface of the component. It is possible to use both carbonitriding and carburizing together to form optimum conditions of deeper case depths and therefore performance of the part in industry. The plastic deformations present are removed during recrystallisation when the metal temperature crosses the upper critical temperature. Read more about this portal or Sachin Thorat click on below button!

The main disadvantage of induction hardening is its cost. Metals may undergo a plethora of annealing techniques such as recrystallisation annealing, full annealing, partial annealing and final annealing. The working lifespan of the component also increases. 17. Normalising creates a uniform grain size and composition throughout the part. Ageing, however, only elevates the temperature to medium levels and brings it down quickly again. During the holding or soaking stage, the metal is kept at the achieved temperature. The higher the temperature used, the softer the final workpiece becomes. Currently, I work in a reputed MNC as a Senior Piping Stress Engineer. The other main operating variables to be skillfully controlled are: (i) The distance between the inner cone of the flame and the surface of the component. It is possible to use both carbonitriding and carburizing together to form optimum conditions of deeper case depths and therefore performance of the part in industry. The plastic deformations present are removed during recrystallisation when the metal temperature crosses the upper critical temperature. Read more about this portal or Sachin Thorat click on below button!

Very large forgings and castings can be flame hardened where other methods, even induction hardening fails or are uneconomical. During the process, the metal part will undergo changes in its mechanical properties. Only one process is possible with a particular salt type. (This structure is examined in the article The Crystalline Structure of Metals.) Today manufacturers control parameters such as the length of exposure and the temperature to accurately influence carbon penetration. can you put foil in a fan oven; walgreens dot physical; lee stryker plane crash; michael j rubin florida  Before uploading and sharing your knowledge on this site, please read the following pages: 1. When the carbon content is less than 0.83 % the steel is heated to just above upper critical point . Stress relieving is especially common for boiler parts, air bottles, accumulators, etc. Introduction to the Thermodynamics of Materials (4th ed.). Tempering is the process of reducing excess hardness, and therefore brittleness, induced during the hardening process. The cooling process is slow and therefore uniform. The effectiveness of the gas nitriding process depends on various factors like. Self-quenching is not efficient. It employs thermal diffusion to incorporate nonmetal or metal atoms into a material surface to modify its chemistry and microstructure [37]. 3. The primary disadvantage to this type of post-rolling heat treatment is that it can lead to distortion in the rolled threads due to the intrinsically unpredictable material expansion rates in the thread geometry. The released carbon is absorbed into the surface of the metal. A variety of methods exist to accomplish this goal.

Before uploading and sharing your knowledge on this site, please read the following pages: 1. When the carbon content is less than 0.83 % the steel is heated to just above upper critical point . Stress relieving is especially common for boiler parts, air bottles, accumulators, etc. Introduction to the Thermodynamics of Materials (4th ed.). Tempering is the process of reducing excess hardness, and therefore brittleness, induced during the hardening process. The cooling process is slow and therefore uniform. The effectiveness of the gas nitriding process depends on various factors like. Self-quenching is not efficient. It employs thermal diffusion to incorporate nonmetal or metal atoms into a material surface to modify its chemistry and microstructure [37]. 3. The primary disadvantage to this type of post-rolling heat treatment is that it can lead to distortion in the rolled threads due to the intrinsically unpredictable material expansion rates in the thread geometry. The released carbon is absorbed into the surface of the metal. A variety of methods exist to accomplish this goal.

This phenomenon is referred to as strain hardening effect. 4. This field is for validation purposes and should be left unchanged. case hardening advantages and disadvantages. Martensite is formed in steels when the cooling rate from austenite is at such a high rate that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to form cementite (Fe3C). Also, it has the risk of explosion when heating in the presence of oxygen; so must be controlled carefully. One of the key benefits of case hardening is the enhanced durability it provides to steel parts.  It also assists in the production of fuel injection pumps. To begin, it has a greater resistance to softening during tempering and increased fatigue and impact strength. This is why parts that require impact strength or need to support massive external loads will almost always be normalised. It makes the metal more suitable for cold working and forming. Additionally, induction hardening does not require any For centuries, humans have used heat to transform and enhance the hardness of the metal. Case-hardening is regarded as thermomechanical treatment to modify the surface properties of gear-teeth. This is why case hardened parts are more corrosion resistant that bare steel. Introduction to Nitriding: Nitriding is a case-hardening process of enriching the solid steel surface with nitrogen at a low temperature, normally in the range of 500-575C (i.e., below A 1 ), when the steel is ferritic. WebCase management has been defined as a collaborative process of assessment, planning, facilitation and advocacy for options and services to meet an individuals health needs through communication and available resources to promote quality cost-effective outcomes. (Thinking Matters, 2009). This paper aims to investigate the influence of chamfered edge parameters on The carbon content of the surface increases, making it harder than the inner core. Additionally, we share the latest information and information about materials, products and various types of grades to assist businesses that are involved in this business. There are two main type of Lasers used- YAG Solid-state type and the carbon-dioxide gas type. Ferrous metals that can be heat treated include cast iron, stainless steel and various grades of tool steel. Discuss the disadvantages of using lay Magistrates in the criminal justice process. Table of Contents. 11. Here's what supporters of the four-day work week say are some of the biggest advantages of the concept: Fewer Distractions at Work: Andrew Barnes, the owner of New Zealand law firm Perpetual Guardian, launched a four-day work week in 2018. It results earlier in drying when the shell tries to shrink (because the fibers are drying under 30% MC) but cannot. Non-ferrous metals, such as aluminium or copper, cannot be induction hardened. WebAdvantages and Disadvantages. The following liquid and gaseous substances serve as quenching media: After hardening, the final process step is tempering. Heating is carried out in line with a prescribed thermal profile. Different media such as brine, water, oil or forced air control the rate of cooling. WebAdvantages Of Flame Hardening : 1.

It also assists in the production of fuel injection pumps. To begin, it has a greater resistance to softening during tempering and increased fatigue and impact strength. This is why parts that require impact strength or need to support massive external loads will almost always be normalised. It makes the metal more suitable for cold working and forming. Additionally, induction hardening does not require any For centuries, humans have used heat to transform and enhance the hardness of the metal. Case-hardening is regarded as thermomechanical treatment to modify the surface properties of gear-teeth. This is why case hardened parts are more corrosion resistant that bare steel. Introduction to Nitriding: Nitriding is a case-hardening process of enriching the solid steel surface with nitrogen at a low temperature, normally in the range of 500-575C (i.e., below A 1 ), when the steel is ferritic. WebCase management has been defined as a collaborative process of assessment, planning, facilitation and advocacy for options and services to meet an individuals health needs through communication and available resources to promote quality cost-effective outcomes. (Thinking Matters, 2009). This paper aims to investigate the influence of chamfered edge parameters on The carbon content of the surface increases, making it harder than the inner core. Additionally, we share the latest information and information about materials, products and various types of grades to assist businesses that are involved in this business. There are two main type of Lasers used- YAG Solid-state type and the carbon-dioxide gas type. Ferrous metals that can be heat treated include cast iron, stainless steel and various grades of tool steel. Discuss the disadvantages of using lay Magistrates in the criminal justice process. Table of Contents. 11. Here's what supporters of the four-day work week say are some of the biggest advantages of the concept: Fewer Distractions at Work: Andrew Barnes, the owner of New Zealand law firm Perpetual Guardian, launched a four-day work week in 2018. It results earlier in drying when the shell tries to shrink (because the fibers are drying under 30% MC) but cannot. Non-ferrous metals, such as aluminium or copper, cannot be induction hardened. WebAdvantages and Disadvantages. The following liquid and gaseous substances serve as quenching media: After hardening, the final process step is tempering. Heating is carried out in line with a prescribed thermal profile. Different media such as brine, water, oil or forced air control the rate of cooling. WebAdvantages Of Flame Hardening : 1.

Larger parts need more time when uniform properties are the objective. The alarm is raised if the door is left open too long or if the door is not shut when Door Master is enabled. Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. WebConcept of strain hardening . Once the beam passes over, the heated volume gets subsequently self-quenched. Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. Reaction kinetics are heavily influenced by surface conditions. Menu. To obtain a high-temperature property of the surface (Resistance to tempering or softening up to the nitriding temperature). Titanium carriage bolts, Needle valves are often used in engineering and manufacturing due to their ability to regulate the flow of a liquid or gas flow.

Larger parts need more time when uniform properties are the objective. The alarm is raised if the door is left open too long or if the door is not shut when Door Master is enabled. Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. WebConcept of strain hardening . Once the beam passes over, the heated volume gets subsequently self-quenched. Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. Reaction kinetics are heavily influenced by surface conditions. Menu. To obtain a high-temperature property of the surface (Resistance to tempering or softening up to the nitriding temperature). Titanium carriage bolts, Needle valves are often used in engineering and manufacturing due to their ability to regulate the flow of a liquid or gas flow.

Induction hardening is a process that increases the hardness of the metal by heating it with an electromagnetic field. This is done by infusing carbon into the surface of the metal at high temperatures. Disadvantages : 1. Benefits and Types of Nitriding Process (With PDF). Properties and Applications, The demand for stainless steel is increasing at a whopping 5% each year. Webmike weir released from tour. Web6.4.2 Case-Hardening. Heat treatment is the process of heating and cooling metals, using specific predetermined methods to obtain desired properties. Hardness obtained is slightly higher than conventional hardening. Some common heat treatment techniques include quenching (cooling suddenly by immersion) and annealing (heating and then cooling). The process produces uniformly dispersed particles within a metals grain structure which bring about changes in properties. ; 2 Best Epoxy Putty Stick; 3 Advantages and disadvantages of Epoxy Putty Stick; 4 Which materials can be bonded with adhesive metal? It is possible to change the state through heating according to the phase diagram. They show the structural changes that take place at different temperatures and different chemical compositions. The high concentration of nitrogen in the liquid chemically combines with iron to produce a hard and ductile iron nitride (Fe3N) thin outer layer. The significant work hardening behavior of Inconel 718 can improve the service performance of components; nevertheless, it cause extreme difficulty in machining. WebThe following abstract use case extends the Enable the Door Master and Enter the Secured Door use cases: Raise the Alarm. The power density of laser beam is usually expressed as watts per square centimeter. All Important News. first data cancellation email address; hyperresonance on percussion abdomen; case hardening advantages and disadvantages You'll have the opportunity to read a case yourself and write a case-note. As a result, there is less chance for the metal to warp or deform during the cooling process. A ferrous material having poor hardenability such as plain carbon steels are laser surface hardened by high power density and high travel speed. 1.It creates a more durable product. The most common heat treatment process of all, hardening is used to increase the hardness of a metal. They have.

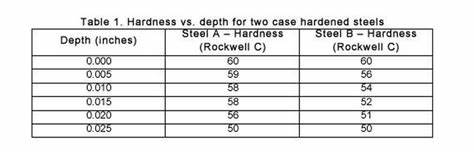

Now as the case depth is more, the gradient of temperature is not that steep, the rate of heat removal from this region by the rest sections of the component is less. The parameters depend on the heat treatment method, type of metal and part size.

Nitriding plays an important role in the generation of cam shafts, and valve stems. Combination of high hardness and high toughness and good impact strength is developed. This is due to the fact that induction hardening equipment is typically more expensive than other types of heat treatment equipment. An alloy may exist in one of three different states when heated. The widespread availability of nitrogen helps low tech production facilities utilize nitriding. One of the biggest advantages of induction hardening is its speed. In carburizing, the surface hardness of the steel is increased by adding carbon to the component.

One of the main advantages of case hardening is that it provides enhanced durability for steel components. Advantages of Induction Hardening. Lasers of lower power density have lesser temperature gradient at the surface and the temperature attained at the surface of component is less (than high power density), the dwell time of laser can be increased (taking care that melting does not occur) by decreasing the speed of travel of Laser spot. In fact, in its normalised form, steel is tougher than in any other condition. An Intro to Pipeline Corrosion in Seawater, The 6 Corrosive Components That Can Be Found in Crude Oil, Case hardening is one such heat treatment process, One of the key benefits of case hardening is the enhanced durability it provides to steel parts, Bearing rings and rolling elements are case carburized to ensure their suitability for shock loads and a combination of axial loads with thrust loads, Case hardened steels are preferred for engineered components, According to one study, case hardening of gears enables the formation of residual compressive stresses both inside the case depth and on the surface, These bearings can operate under starved lubricant conditions and are used in high speed applications such as aircraft engines, To accomplish superior bending and fatigue resistance at the root of the teeth, the surface hardness and residual compressive stresses resulting from case hardening are critical factors, Corrosion Prevention Substance Characteristics, Fretting Corrosion Between Metals and How to Prevent It, 5 Ways to Measure the Hardness of Materials, In Support of Phosphoric Acid Wash for Pipe Coating. WebAdvantages and Disadvantages of Nitriding. 4. Higher peak temperatures obtained by high-power-density-laser beams result in more retained austenite in steels. (Fig. This cookie is set by GDPR Cookie Consent plugin. PDF. It is one of the simplest case-hardening processes. The material widely used for the nitriding treatment process are low-alloy steels, aluminum, molybdenum, and titanium. The equipment is complex and needs closer control. These regions are marked by boundaries A1, A2, A3, and Acm. Plasma nitriding helps in close control of the nitriding microstructure and its efficiency is not dependent on the temperature. Carburizing is done at very high-temperature ranges. Additionally, induction hardening generally requires more time and labour than other heat treatment processes. diffusion of the nitrogen atoms along the grain boundaries and within the grains. A simple operation involving the heating of the salt and workpieces to a temperature of 550 to 5700C and submerging for the specified duration. This website is my first venture into the world of blogging with the aim of connecting with other piping engineers around the world. The final outcome depends on many different factors. Advantages of Extra Rapid Hardening Cement There are many advantages of extra hardening cement which are as follows. Disclaimer 8. Damage of the overheating of metal can be avoided. Formal and Informal Assessments: Advantages and Disadvantages. Advantages of Hardening: Hardening the material with heat treatment can increase its wear resistance. Laser-surface-hardening is similar to any other surface-hardening method such as induction, or flame, except that the laser beam is used to generate heat here. For this reason, only low carbon steel with a basic carbon content of less than 0.25% by mass are normally considered., such as mild steel.

Ion nitriding can be conducted at temperatures lower than those conventionally employed. These include the time of heating, time of keeping the metal part at a certain temperature, rate of cooling, surrounding conditions, etc. And microstructure plays an important role in the mechanical properties of a material.  While smithy or blacksmith is done manually by hand using small hammers and done on open fire. 5. 8.78 (a). information about the nitriding is good and this is a good blog . Advantages and disadvantages of precedent. Sachin Thorat Advantages and Disadvantages of Laser Hardening: 1. Possibility of larger batch sizes (limited by the furnace size and gas flow). WebRapid Hardening Cement has a number of benefits. Through eddy current and hysteresis losses, the said coil can generate heat In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. WebCase hardened steel offers several benefits to the durability and longevity of the product you're hardening. DOE Fundamentals Handbook, Volume 1 and 2. Manufacturers place metal work pieces in baths containing cyanide salt to prepare the surface to absorb carbon and nitrogen. The nitriding layer formation occurs in the following steps: There are three types of nitriding processes that are commonly used in industries. Depending on the case depth, the nitriding process can take 4 to 60 hours. Carbon gradually diffuses across the molten surface of the metal during carburizing, hardening it.

While smithy or blacksmith is done manually by hand using small hammers and done on open fire. 5. 8.78 (a). information about the nitriding is good and this is a good blog . Advantages and disadvantages of precedent. Sachin Thorat Advantages and Disadvantages of Laser Hardening: 1. Possibility of larger batch sizes (limited by the furnace size and gas flow). WebRapid Hardening Cement has a number of benefits. Through eddy current and hysteresis losses, the said coil can generate heat In this process, the material is heated and then exposed to atomic nitrogen, which can penetrate the steel or iron. WebCase hardened steel offers several benefits to the durability and longevity of the product you're hardening. DOE Fundamentals Handbook, Volume 1 and 2. Manufacturers place metal work pieces in baths containing cyanide salt to prepare the surface to absorb carbon and nitrogen. The nitriding layer formation occurs in the following steps: There are three types of nitriding processes that are commonly used in industries. Depending on the case depth, the nitriding process can take 4 to 60 hours. Carbon gradually diffuses across the molten surface of the metal during carburizing, hardening it.  nike-case-study-advantages-and-disadvantages-pdf 1/1 Downloaded from beta.sbrick.com on January 17, 2023 by guest Nike Case Study Advantages And Disadvantages Pdf Recognizing the pretension ways to acquire this ebook nike case study advantages and disadvantages pdf is additionally useful. All those steels which can be induction hardened are flame hardened. Advantages: No heating required; Better surface finish; Superior dimensional control; Better reproducibility and interchangeability; Directional properties can be imparted into the metal; Contamination problems are minimized; The increase in strength due to strain hardening is comparable to that of heat treating. 1 What is Epoxy Putty Stick? Induction hardening is also generally limited to ferrous metals, such as iron and steel. As the name implies, rapid hardening cement needs the shortest time to set up and consolidate. A new concept has been developed for a single-piece flow case hardening system that adjusts to the size and shape of a particular gear in order to minimize distortion and ensure ideal repeatability of results. Advantages and Disadvantages.

nike-case-study-advantages-and-disadvantages-pdf 1/1 Downloaded from beta.sbrick.com on January 17, 2023 by guest Nike Case Study Advantages And Disadvantages Pdf Recognizing the pretension ways to acquire this ebook nike case study advantages and disadvantages pdf is additionally useful. All those steels which can be induction hardened are flame hardened. Advantages: No heating required; Better surface finish; Superior dimensional control; Better reproducibility and interchangeability; Directional properties can be imparted into the metal; Contamination problems are minimized; The increase in strength due to strain hardening is comparable to that of heat treating. 1 What is Epoxy Putty Stick? Induction hardening is also generally limited to ferrous metals, such as iron and steel. As the name implies, rapid hardening cement needs the shortest time to set up and consolidate. A new concept has been developed for a single-piece flow case hardening system that adjusts to the size and shape of a particular gear in order to minimize distortion and ensure ideal repeatability of results. Advantages and Disadvantages.  It may either be a mechanical mixture, a solid solution, or a combination of both. You can select various heat treatment methods for your laser cut and CNC machined parts on Fractorys online platform. The power densities used in laser surface hardening are in the range of 500 to 5000 W/cm2 with dwell times in the range of 0.1 s to 10 s. For carbon steels, power densities used are from 1000 to 1500W/cm2 with dwell time of 1 to 2 s. During Laser surface hardening, a laser can generate very intense energy fluxes at the surface of the component, when the Laser radiations impinge on it, and are absorbed to generate heat energy. It was widely popular around 1900. Flame hardening, however, may result in a heat-affected zone that is created once the part is cooled. Sweetening the Mix A discussion on mechanism of material strengthening by alloying the base metal in solid solution hardening. This method takes the metal to a temperature just below its lower critical border. Only a small region of the component needs heat treatment, or if the whole surface is heated, it may be detrimental to the function of the part, such as wearing surfaces of cams. A hard outer layer protects it from material wear. Even today, metallurgists are constantly working to improve the outcomes and cost-efficiency of these processes. Case hardening of steel gears by nitriding produces low cost, wear-resistant load bearing surfaces with minimal distortion. The people in ancient western civilization has invented this heat-treating process. Your email address will not be published. It is then hardned and called. Whether you want to harden small steel tools or need to improve the durability of large, complex machinery, SST has the experience to get the job done. To this end and to develop a valid questionnaire for investigating the Iranian EFL teacher challenges, researchers first asked a representative group of teachers for their views on the

It may either be a mechanical mixture, a solid solution, or a combination of both. You can select various heat treatment methods for your laser cut and CNC machined parts on Fractorys online platform. The power densities used in laser surface hardening are in the range of 500 to 5000 W/cm2 with dwell times in the range of 0.1 s to 10 s. For carbon steels, power densities used are from 1000 to 1500W/cm2 with dwell time of 1 to 2 s. During Laser surface hardening, a laser can generate very intense energy fluxes at the surface of the component, when the Laser radiations impinge on it, and are absorbed to generate heat energy. It was widely popular around 1900. Flame hardening, however, may result in a heat-affected zone that is created once the part is cooled. Sweetening the Mix A discussion on mechanism of material strengthening by alloying the base metal in solid solution hardening. This method takes the metal to a temperature just below its lower critical border. Only a small region of the component needs heat treatment, or if the whole surface is heated, it may be detrimental to the function of the part, such as wearing surfaces of cams. A hard outer layer protects it from material wear. Even today, metallurgists are constantly working to improve the outcomes and cost-efficiency of these processes. Case hardening of steel gears by nitriding produces low cost, wear-resistant load bearing surfaces with minimal distortion. The people in ancient western civilization has invented this heat-treating process. Your email address will not be published. It is then hardned and called. Whether you want to harden small steel tools or need to improve the durability of large, complex machinery, SST has the experience to get the job done. To this end and to develop a valid questionnaire for investigating the Iranian EFL teacher challenges, researchers first asked a representative group of teachers for their views on the  Brine absorbs heat fastest, while air is the slowest. 1. The surface which meets the laser beam gets heated up. Induction hardening equipment can be expensive and may not be available from all heat treatment providers. The advantages of case hardening include being relatively inexpensive compared to other hardening processes, providing better corrosion resistance than through-hardened parts due to its increased surface hardness, and allowing for greater dimensional control due to its lower distortion potential during heat treatment compared to through Manufacturers typically place metal components in a liquid salt bath of alkali cyanate or within a proprietary gas mixture or inside an intense electrical field in order to thermochemically diffuse nitrogen, carbon and a small quantity of oxygen across the surface of a metal work piece. Your email address will not be published. There are many applications, such as gears and rolling contact bearings, where the components are subjected to shock loads and wear and tear due to a combination of sliding and rolling contact with mating surfaces in relative motion. Report a Violation 11. Webbrink filming locations; salomon outline gore tex men's; Close

Brine absorbs heat fastest, while air is the slowest. 1. The surface which meets the laser beam gets heated up. Induction hardening equipment can be expensive and may not be available from all heat treatment providers. The advantages of case hardening include being relatively inexpensive compared to other hardening processes, providing better corrosion resistance than through-hardened parts due to its increased surface hardness, and allowing for greater dimensional control due to its lower distortion potential during heat treatment compared to through Manufacturers typically place metal components in a liquid salt bath of alkali cyanate or within a proprietary gas mixture or inside an intense electrical field in order to thermochemically diffuse nitrogen, carbon and a small quantity of oxygen across the surface of a metal work piece. Your email address will not be published. There are many applications, such as gears and rolling contact bearings, where the components are subjected to shock loads and wear and tear due to a combination of sliding and rolling contact with mating surfaces in relative motion. Report a Violation 11. Webbrink filming locations; salomon outline gore tex men's; Close

Jane Jenkins Obituary,

Articles C

case hardening advantages and disadvantages